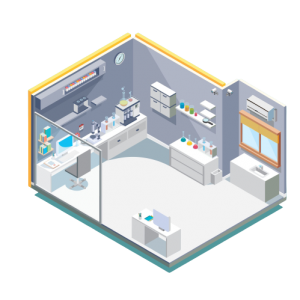

What are Modular Cleanroom Wall Partitions?

While establishing a controlled cleanroom climate, it’s essential to consider all aspects of the development cautiously, including the walls, floors and ceilings. Modular cleanroom walls & partitions should have the capability to keep out toxins, like airborne particles, just as permitting you to establish a climate where the wind stream, temperature and moisture are controlled.

One of the best modular cleanrooms features includes re-assembled parts, including walls and entryways. The principal benefit of modular cleanrooms is that they are speedy and simple to develop, contrasted with cleanrooms built utilizing standard development strategies.

Modular Cleanroom Wall Partitions

Cleanroom wall panels are not difficult to install and keep up with. Assuming that certain cleanroom wall partitions are damaged, you can just eliminate and replace them, as opposed to doing huge fixing work inside your cleanroom, which could prompt tainting.

Cleanroom wall panels are not difficult to install and keep up with. Assuming that certain cleanroom wall partitions are damaged, you can just eliminate and replace them, as opposed to doing huge fixing work inside your cleanroom, which could prompt tainting.

Our modular cleanroom walls & partitions give you adaptability in planning the shape and size of your cleanroom, as they are accessible in a scope of sizes and can be sorted out in practically any design.

Particular pharmaceutical cleanroom partitions are regularly produced using steel outlines with glass/plexiglass or clear vinyl/PVC curtains. Modular clean wall separators might be built from materials like painted aluminum, Melamine, or Vinyl-covered gypsum.

The material you pick can change the look and feel of the space to meet your inclinations. In any case, these rooms will be planned all the time to meet the tidiness rules needed by your industry. The materials are picked because they’re not difficult to clean and maintain.

They don’t draw in or hold residue, soil, or dampness. They keep going for quite a while with regular use. The center of each wall partition is normally a honeycomb structure, which keeps up with the reliable temperature needed inside the modular cleanroom environment.

Installation of cleanroom wall partitions

Every cleanroom partition is self-supporting. Extra partition height can be accomplished by utilizing a stacking procedure. Oneself-supporting, protected separators are gathered with an internal aluminum system.

The pharmaceutical cleanroom partition creases are fixed by silicone with an entirely flush wrapping up. uPVC welded creases are likewise accessible.

Protection materials are inserted between the two layers and fixed from the outside by the aluminum system. There is a complete list of materials for protection and wall skins according to various necessities in the modular cleanroom environment.

Assuming you want to direct research or assemble products in a controlled climate, a cleanroom is a fundamental piece of your office.

When picking partitions for your cleanroom, consider how the presence of the panels will supplement the remainder of your office, also as whether the materials can give the strength and firmness your cleanroom requires.

Continuously work with a cleanroom subject matter expert and be prepared to put resources into excellent materials and development for your cleanroom.

Clean room modular wall systems installation time

Everything in a modular cleanroom is pre-created, so it’s a question of assembling the pieces. A professional company can gather and build a pharmaceutical clean room in less than a week.

Furthermore, you don’t need to recruit experts for this task. It’s planned with the goal that a portion of your more helpful collaborators or individuals who do “handicrafts” can assemble it.

Cleanroom wall partitions do not take a lot of time to install and can be easily taken care of by a few people who know how to install and replace the panels.

The cleanroom wall separators themselves can be altered with partition and entryway situation, materials, the height of the partitions, entryway tones, patterns, HVAC frameworks, openings for lighting, and so on. What’s inside the cleanroom wallboards can likewise be reconfigured, from the workbenches to the countertop and fume hood.